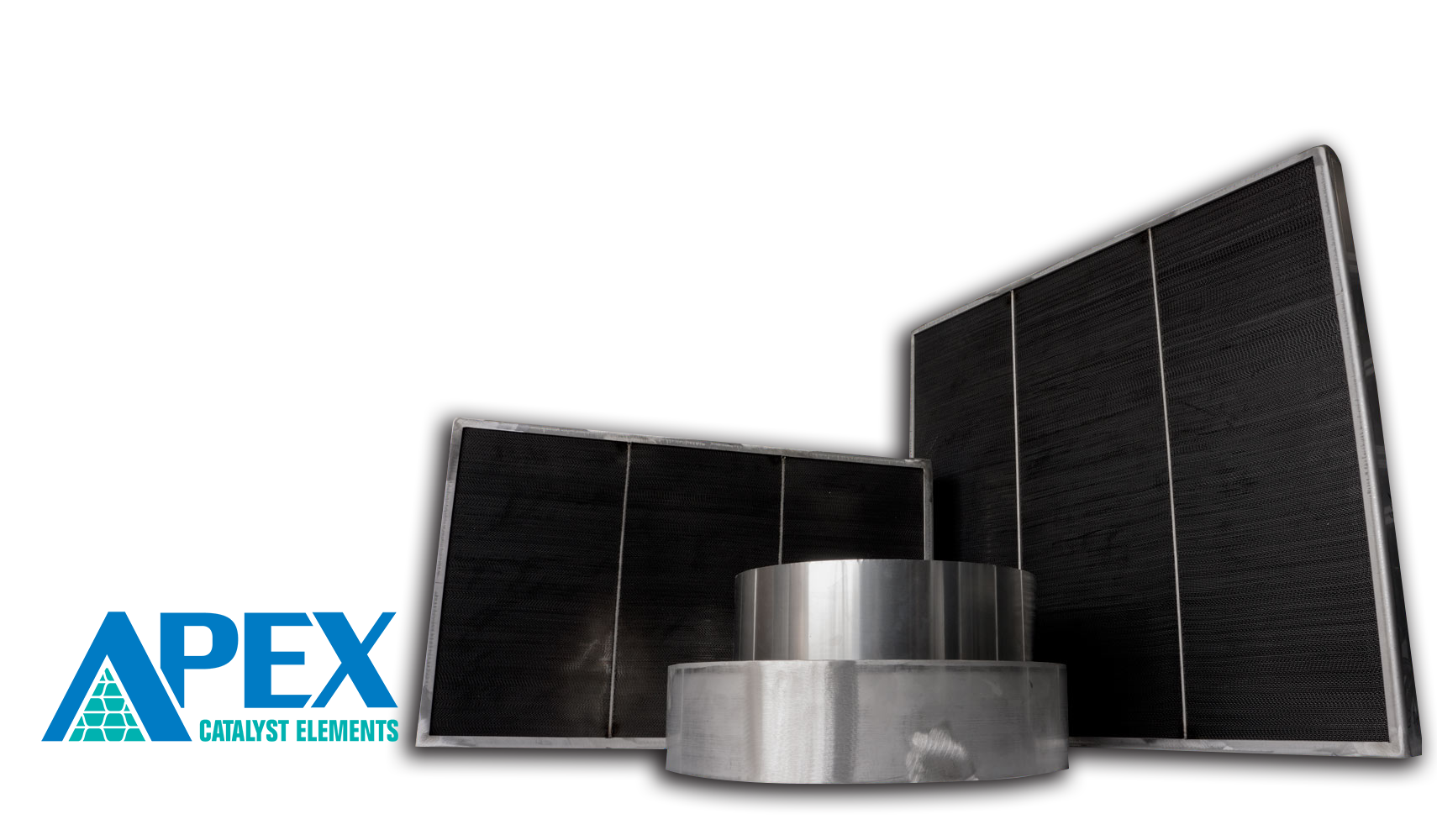

Apex CO Oxidation Catalysts

Owners/operators face the challenge of exhaust emissions on their lean-burn natural gas, propane, or dual-fuel industrial engines. Because there’s excess air in the lean-burn fuel mix and exhaust stream, bringing carbon monoxide (CO), hydrocarbons (HC), volatile organics (VOCs), aldehydes, and other hazardous air pollutants (HAPs) to acceptable levels can be a challenging task. Apex Oxidation Catalyst is designed specifically for these types of applications.

Available in a wide range of sizes and shapes, Apex CO Oxidation Catalysts can be custom-tailored to fit virtually any space requirements, used in any brand of catalytic converters, and worked into any budget. Also for operators with load-variant applications, it can be an affordable, effective, no-hassle solution in dealing with CO, HC, VOCs and HAPs emissions control. Apex catalysts are proudly made in the USA.

Product Data

- Destructive Efficiencies: up to 99%

- Pressure Drop: Variable; quoted per specifications

- Working Range: from 550° F up to 1250° F

- Catalyst Substrate:

- Metal honeycombs up to 48” square, round or oblong

- Cell densities from 20 cpsi to 700 cpsi

- Catalyst module depth from 3/4” up to 6”

- Foil thickness of 0.002″

Features & Benetfits

- Low pressure drop

- Wide operating temperature range

- Easily cleaned and reactivated

- No nesting or telescoping design

- Variety of cell densities

- Parallel flow reduces plugging

- Custom designed based on application

- Test cores for aging assessment

Emission Sources

- IC Engines

- Broilers

- Gas Turbine

- Chemical Processes

Fuels

- Natural Gas

- Diesel

- LPG

- Propane

- Bio-diesel

- Dual Fuel

Emission Compliance

- NOx

- CO

- HCs

- VOCs

Plus

- Platinum Only

- Crystal Size

- Telescopic Bars

- No Brazing

- In-House Laboratory

- In-House Production

- Quality Control