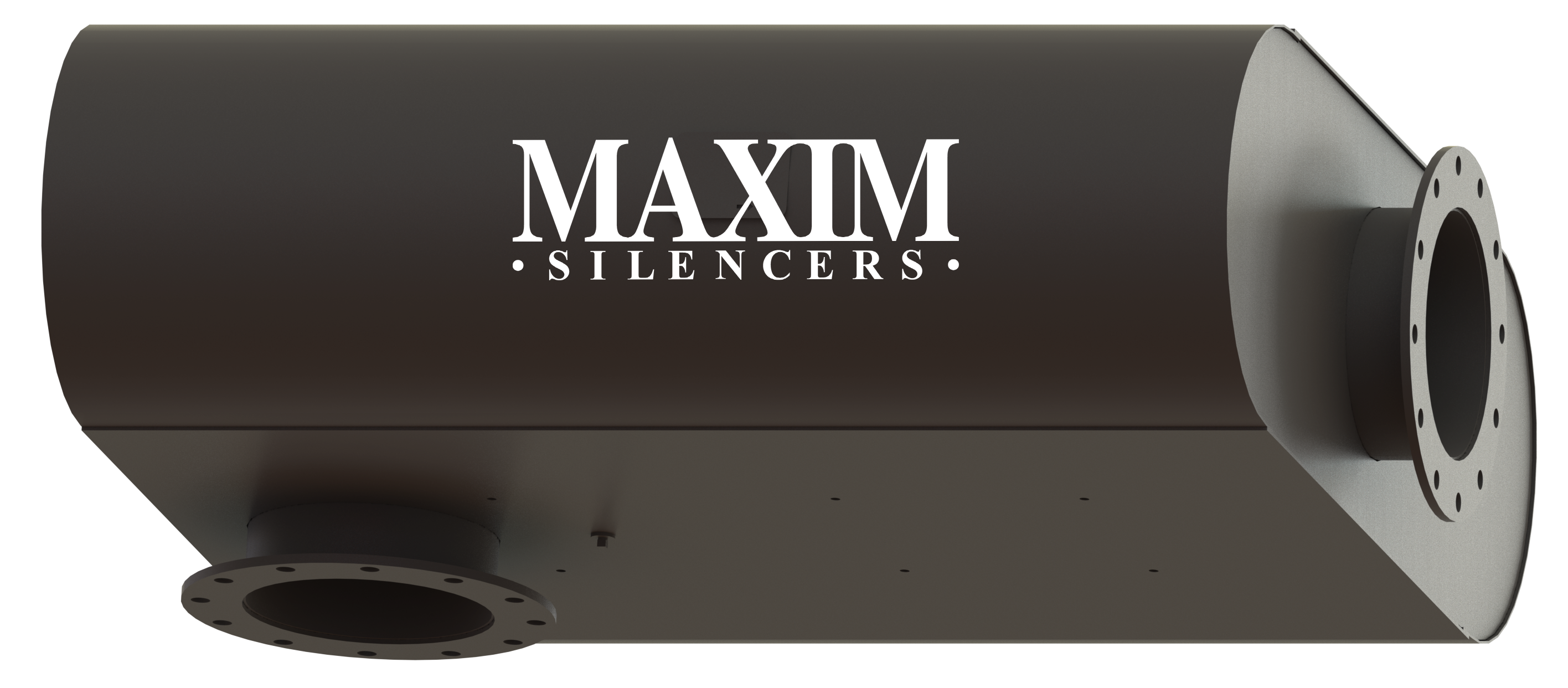

Exhaust Silencers

Maxim Silencers engineers and builds industrial silencers for noise control in the oil & gas industry, the power generation market, and other industries. Maxim Silencers are the toughest available. Chambered for low frequency or packed for high frequency noise attenuation; combine both for extreme applications. Standard Cylindrical Chamber, Compact Disk Chamber, Thin Line Oval, Spark Arresting, Low Pressure, Straight Through, Blower & Marine/Wet Exhaust

Maxim M Series Cylindrical Chamber silencers provide the best noise control across the entire audible range. The basic design incorporates non-resonant side tube arrangements to permit passage of the exhaust gases from one chamber to another. This creates a reversal of flow and develops a predictable amount of back pressure. Another important feature of chamber type silencers is the availability of side inlet exhaust connections. These units can also have side outlet exhaust connections. These side connections, while having little effect on the pressure drop, will in many instances greatly facilitate installation of the silencer by eliminating the need for elbows in the exhaust piping. Click here to learn more about the M Series

Maxim MSA Series Spark arresting chamber silencers. Spark arresting applications include marine service, refineries and other hazardous environments. These units have chamber type designs. The retention of hot carbon and soot particles minimizes danger and helps provide a cleaner area and atmosphere.Click here to learn more about the MSA Series

Maxim SU DNV Spark Arresting Chamber DNV Type Approved spark arresting silencer designed for equipment operating in environments containing potentially combustible materials. The silencer forces cyclonic action to separate particulates from exhaust. The collected particulates are removed via the spark clean-out. Providing an exceptional level of attenuation, it is designed for very quiet environments. Click here to learn more about the SU DNV Series

Maxim MT Series Low Pressure/Straight through silencers have an unobstructed passage through the silencer with no flow reversal. The result is a pressure drop across the silencer only slightly above that caused by an equivalent length of pipe. Side connections are not practical in this design due to an increase in pressure drop and price. Noise attenuation provided by straight through design is less than that provided by chamber design silencers incorporating a flow reversal. As a result, the MT series is best used in applications where low pressure drop is the primary consideration. Click here to learn more about the MT Series

Maxim MP Series Marine Engine/Wet Exhaust silencers are constructed of 316L stainless steel and available for wet marine engine exhaust applications. Water is injected upstream of the silencer in sufficient quantity to reduce the exhaust temperature to a maximum of 200ºF. The MP11 may be installed in series with an MP31 or MP41 to provide additional attenuation.Click here to learn more about the MP Series

Maxim MD Series Low profile compact disk chamber silencers are engineered to provide "Residential" to "Hospital" grade attenuation, while minimizing space usage. They are an excellent choice for packaged power and process skids where space is a premium. Dual inlets and other custom designs can be easily incorporated. Low temperature design not only reduces skin temperature, but radiated noise as well. These units feature heavy duty, welded construction with temperature resistant insulation within a double wall construction. The inlet and outlets are standard with ANSI drilled 125/150 lb flanges. Standard finish is high temperature resistant silicone black. Alternate finishes are available upon request. Standard material is carbon steel, but stainless steel construction is available.Click here to learn more about the MD Series

Maxim MR Series Thin Line Oval chamber silencers are engineered to provide "critical" to "extreme" grade attenuation, while minimizing space usage. They are an excellent choice enclosures and marine applications where height and space is a premium. Dual inlets and other custom designs can be easily incorporated. Low temperature design not only reduces skin temperature, but radiated noise as well. These units feature heavy duty, welded construction with temperature resistant insulation within a double wall construction. The inlet and outlets are standard with ANSI drilled 125/150 lb flanges. Standard finish is high temperature resistant silicone black. Alternate finishes are available upon request. Standard material is carbon steel, but stainless steel construction is available. Click here to learn more about the MR Series

Maxim MB Series Blower Silencers featuring a highly efficient acoustic design, and is used to reduce the noise radiating from blower piping or the blower opening. Typical applications are rotary positive blower intake and discharge, vacuum pump intake and discharge, and centrifugal blower intake and discharge. Click here to learn more about the MB Series