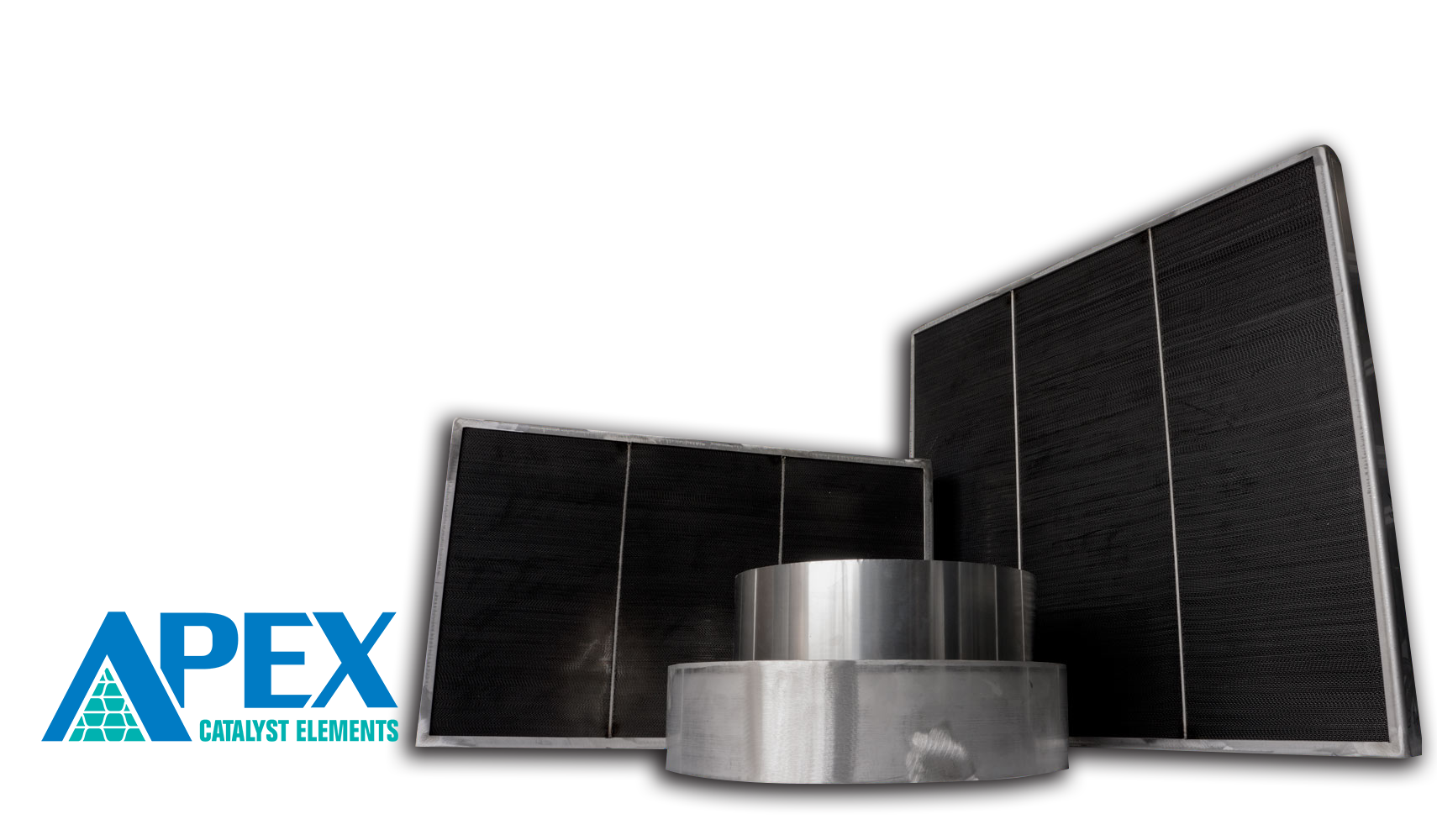

Apex NSCR Three-Way Catalysts

If you run rich-burn stationary natural gas or propane-fueled industrial engines, you face tough compliance rules and stiff non-compliance fines that cover several types of exhaust emissions – carbon monoxide (CO), oxides of nitrogen (NOx), hydrocarbons (HCs), volatile organic compounds (VOCs), and a long list of EPA-classified hazardous air pollutants (HAPs). The good news… One cost-effective, high performance, easy-maintenance Apex catalyst element helps bring your operation within compliance.

We can provide standard catalysts; Available in a wide range of sizes and shapes, the 3-way catalyst can be custom-tailored to fit virtually any space requirements, any brand of catalytic converter, and any budget. For operators in energy infrastructure, air compression, water, petroleum or liquids pumping, chillers and power generation, and a variety of other applications, Apex 3-way can be a breath of fresh air! It is an affordable, effective, no-hassle answer to the emissions rules for rich-burn industrial engines. Apex catalyst are proudly made in the USA.

Product Data

- Destructive Efficiencies: up to 99%

- Pressure Drop: Variable; quoted per specifications

- Working Range: from 550° F up to 1250° F

- Catalyst Substrate:

- Metal honeycombs up to 48” square, round or oblong

- Cell densities from 20 cpsi to 700 cpsi

- Catalyst module depth from 3/4” up to 6”

- Foil thickness of 0.002″

Features & Benetfits

- Low pressure drop

- Wide operating temperature range

- Easily cleaned and reactivated

- No nesting or telescoping design

- Variety of cell densities

- Parallel flow reduces plugging

- Custom designed based on application

- Test cores for aging assessment

Emission Sources

- IC Engines

- Broilers

- Gas Turbine

- Chemical Processes

Fuels

- Natural Gas

- Diesel

- LPG

- Propane

- Bio-diesel

- Dual Fuel

Emission Compliance

- NOx

- CO

- HCs

- VOCs

- HAPs

Plus

- Platinum Only

- Crystal Size

- Telescopic Bars

- No Brazing

- In-House Laboratory

- In-House Production

- Quality Control